Introduction

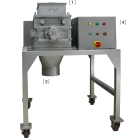

It is designed for the efficient processing of both dry and wet materials, particularly those that are heat-sensitive or difficult to handle.This equipment utilizes a rotary-pendulum cutting mechanism. By adjusting the oscillation speed of the rotor and selecting an appropriate screen type, optimal milling performance can be achieved for various materials.Depending on material characteristics, users can choose between round-wire mesh, square-wire mesh, or perforated plate screens.

Features

1.Low-speed milling significantly reduces heat generation.

2.Robust base structure ensures precise clearance between rotor and screen, eliminating any metal-to-metal contact.

3.Durable, maintenance-free design for long service life.

4.Suitable for both dry and wet granules, ideal for heat-sensitive materials and wet granulation applications.

5.No direct contact between rotor and screen; the gap is infinitely adjustable.

6.Modular design enables flexible integration into complete processing lines.

7.Quick disassembly of screen, rotor, and base for easy cleaning and maintenance.

8.Various screen types available: round-wire, square-wire, or perforated plates.

9.Optional WIP system with integrated spray nozzles for in-place cleaning.

10.Customizable options for waterproofing, dustproofing, and explosion protection.

11.Complies with CIP/SIP/NIP requirements and meets FDA/GMP certification standards.

11.Accords with CIP, SIP/WIP, meet with FDA/GMP audit requirements.

|

easy-cleaning grinding revolving drum |

slide screen structure, no tool needed, no blind angle |

Material

|

Device |

Direct Contact Part |

Other Part |

|

Metal Material |

SUS316L |

SUS304 |

|

Seal Ring |

FDA accredited, silicon rubber |

Various materials |

|

Surface Smoothness |

Ra≤0.4μm |

Ra≤0.8μm |

|

Welding Joint |

Polishing and puffing |

Acid pickling and sanding |

|

Sieve Mesh |

~60 |

|

|

Gap Between Rotor & Screen |

0~6mmAdjustable |

|

|

Revolution Speed |

Stepless control with hand wheel |

|

Parameter

|

Model |

Capacity |

Voltage |

Rotor Speed |

Power |

Net Weight |

|

|

Without Base |

With Base |

|||||

|

BFJ-10 |

300~800kg/h |

3×380v-50Hz |

27~155rpm |

2.2kW |

285kg |

335kg |

|

BFJ-15 |

500~1500kg/h |

3×380v-50Hz |

27~155rpm |

2.2kW |

320kg |

370kg |