Introduction

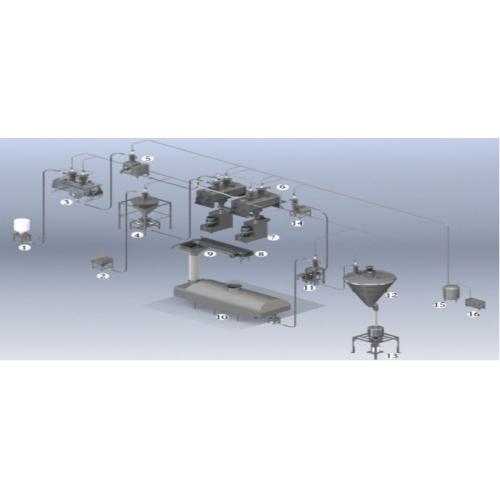

Pelletizing production line is the automatic production line which produces raw materials into pellets according to user’s request in fully sealed condition. Operator feed different materials into discharge hopper respectively. Then materials are conveyed to stirring bin to be fully stirred. Vacuum feeder conveys proportionate materials into wet stirring bin and after stirring, screw conveyer send materials respectively into AOI extruding rounding machine. Granules from rounding machine are dried by vibration dryer. Qualified pellets will be directly conveyed into finished products bin to be weighed, metal-detecting and packaged while the unqualified will be transferred back to wet stirring bin to be reworked.

The whole production line works automatically with PLC in fully sealed condition, pollution-free and controlled by ICC (Industrial Control Computer). It meets the requirements of new version GMP.

Major Equipment

Sack opening machine, vacuum conveyor, stirring bin, weighing measuring tank, screw conveying equipment, AOI extruding rounding machine, belt conveying device, vibrating dryer, screening device, weight metering filling device, heat seal machine, metal-detector, weight-check machine, box filler.

1. Sack Bag Opening Machine 2. Small Bag Feeding Machine

3. Paralleling Vacuum Feeding Machine + Stir Bin

4. Vacuum Feeder + Weighing Measuring Tank (A material)

5. Vacuum Feeder + Weighing Measuring Tank (A material)

6. Vacuum Feeder + Wet Stirring Bin

7. AOI Extruding Rounding Machine

8. Conveyor

9. Discharge hopper

10. Vibration Dryer

11. Vacuum Feeder + Sifting Machine + Metal Detector

12. Finished Products Bin 13. Automatic Weighing Machine

14. Vacuum Equipment + Pulverizer 15. Vacuum Bin

16. Vacuum Unit