Introduction

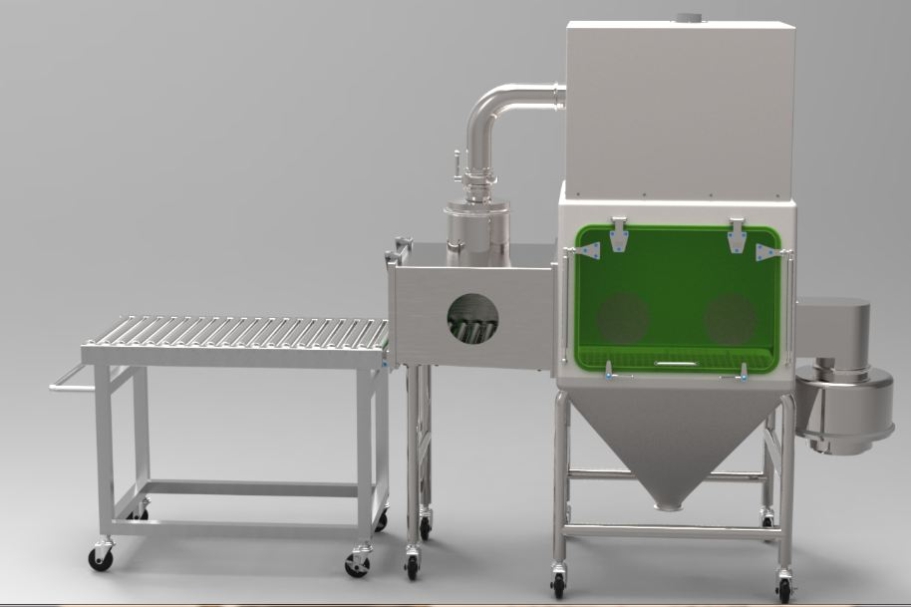

1.Material bags are transferred into the isolation glovebox via conveyor rollers through a pass-through chamber.

2.Manual bag opening and discharging through glove ports.

3.Spent bags are automatically collected by waste disposal unit.

4.Totally dust-free operation process.

5.Clean-in-Place (CIP) capability.

6.Custom-engineered design.

Application

1.Safe handling of corrosive or toxic powders.

2.Contained transfer of high-value powders.

3.Integrable with vacuum conveying systems to form closed material handling circuits.